Introduction to DTF Printing

Definition of DTF (Direct-to-Film) Printing

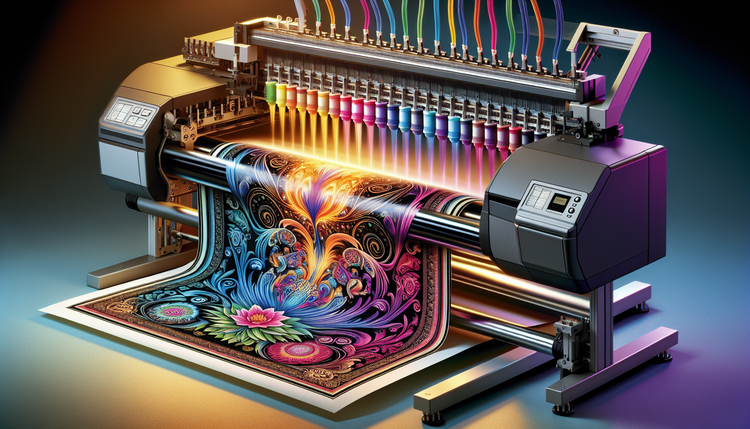

Direct-to-Film (DTF) Printing is a cutting-edge technique that enables high-quality, vibrant prints on various materials and fabric types. It utilizes specialized printers, inks, and films to create detailed, long-lasting designs.

Brief history and evolution of DTF Printing

DTF Printing has evolved from traditional printing methods, incorporating technological advancements to enhance efficiency, accuracy, and sustainability. This innovative process continues to gain momentum in the textile and apparel industries.

Importance of DTF Printing in the apparel and textile industry

As a versatile and eco-friendly printing method, DTF Printing plays a crucial role in the apparel and textile industry. It allows for high-quality prints with minimal waste, making it an attractive option for businesses looking to optimize their processes and reduce their environmental impact.

Understanding the DTF Printing Process

In order to fully grasp the advantages and potential of DTF Printing, it's essential to understand the process behind it. This includes the role of DTF printers, ink, and film, as well as a step-by-step guide to the DTF Printing process.

The Role of DTF Printers, Ink, and Film

DTF Printing relies on specialized printers that are designed specifically for this technique. These printers utilize high-quality DTF inks that enable vibrant, long-lasting prints on various materials. Additionally, the process involves printing on a specific type of film, which serves as a medium to transfer the design onto the desired material or fabric.

Step-by-Step Guide to the DTF Printing Process

Understanding the DTF Printing process involves following a series of steps that ensure a successful and high-quality print. These steps include:

Digital Design Creation: The process begins with creating a digital design using graphic design software. This design serves as the blueprint for the final print.

Fabric Preparation: The material or fabric to be printed on is prepared, ensuring it is clean and free from any debris or imperfections that could affect the print quality.

Printing on the Film: The digital design is then printed onto the DTF film using the specialized DTF printer and ink. This process transfers the design from the digital realm to a physical medium.

Powdering: A layer of adhesive powder is applied to the printed film. This adhesive powder will later help the design adhere to the fabric during the transfer process.

Melting the Powder: The film is heated to melt the adhesive powder, creating a bond between the design and the film.

Pre-pressing: The fabric is pre-pressed to ensure a smooth and even surface for the design transfer.

DTF Transfer: The film, with the design and adhesive powder, is placed on the fabric and pressed using a heat press. This process transfers the design onto the fabric, adhering it securely.

Cold Peel: After allowing the fabric to cool, the film is carefully peeled away, leaving the design on the fabric.

Post-pressing: The fabric is pressed again to ensure the design is fully bonded and set in place.

Final Touches: Any necessary finishing touches are applied, such as trimming or additional embellishments, resulting in a high-quality, vibrant, and long-lasting DTF print.

DTF Printing Market Status

As the Direct-to-Film (DTF) Printing technique continues to gain traction in the apparel and textile industries, it's essential to understand the current market trends and potential growth prospects.

Current trends and market size: DTF Printing has witnessed significant growth in recent years due to its numerous advantages, such as high-quality prints, versatility, and eco-friendliness. This has led to an increase in the adoption of DTF Printing technology by various businesses, contributing to the overall growth of the market. The market size for DTF Printing is expected to expand further as more companies recognize the benefits of this innovative technique and invest in the necessary equipment and supplies.

Potential growth and future prospects: The future of DTF Printing looks promising, with the potential for even more growth in the coming years. As technology continues to advance, there will likely be improvements in DTF Printing equipment and processes, further enhancing the technique's efficiency and capabilities. Additionally, the increasing demand for sustainable and eco-friendly printing solutions is expected to drive the popularity of DTF Printing, as it addresses these concerns while maintaining high-quality results. As a result, businesses investing in DTF Printing technology can anticipate a strong return on investment and a competitive edge in the market.

DTF Printed Products and Services Offered by DTF Transfer Zone

DTF Transfer Zone is a leading provider of DTF Printing solutions, catering to various needs and requirements in the apparel and textile industries. They offer a comprehensive range of products and services, ensuring high-quality and efficient results for their customers. Some of the key offerings by DTF Transfer Zone include:

Custom DTF transfers: DTF Transfer Zone specializes in creating custom DTF transfers, allowing businesses to create unique, vibrant, and long-lasting designs on a wide range of materials and fabric types. This service ensures that each print is tailored to meet the specific needs of the client, resulting in an end product that truly stands out.

DTF ink and supplies: To achieve the best possible results, DTF Transfer Zone offers high-quality DTF inks and supplies. These products are designed specifically for use with DTF printers, ensuring vibrant colors and exceptional print quality.

Ready-to-press heat transfers for various occasions: Catering to different events and celebrations, DTF Transfer Zone provides ready-to-press heat transfers that can be easily applied to various materials. This service allows for quick and easy customization of products, perfect for businesses looking to offer unique and personalized items for special occasions such as birthdays, holidays, and more.

Custom holiday gifts: DTF Transfer Zone also offers custom holiday gifts, including sweatshirts, hoodies, pajama pants, and printed blankets. These products can be personalized with unique designs, making them perfect gifts for friends, family, and customers during the holiday season.

Fast shipping and processing times: Understanding the need for quick turnaround times, DTF Transfer Zone prioritizes fast shipping and processing. They offer 2-4 day processing times, free ground shipping on orders over $250, and even same-day printing availability for certain orders, ensuring that customers receive their products promptly and efficiently.

Advantages of DTF Printing

Direct-to-Film (DTF) Printing offers numerous advantages that make it an attractive option for businesses in the apparel and textile industries. Some of the key benefits of DTF Printing include:

High-quality prints and vibrant colors: DTF Printing is renowned for producing exceptionally high-quality prints with vivid colors. This is due to the specialized DTF inks and printers used in the process, which ensure that the final product is both visually stunning and long-lasting.

Versatility in printing on different materials and fabric types: Another major advantage of DTF Printing is its versatility. This printing technique can be used on a wide range of materials and fabric types, including cotton, polyester, and blended fabrics. This flexibility allows businesses to cater to a diverse range of customer needs and preferences, expanding their product offerings and market reach.

Environmentally friendly process: DTF Printing is an eco-friendly printing method, as it produces minimal waste and uses fewer resources compared to traditional printing techniques. This makes it an ideal choice for businesses looking to reduce their environmental impact and meet the growing demand for sustainable products and processes.

No setup or art fees: One of the cost-saving benefits of DTF Printing is that there are no setup or art fees involved. This means that businesses can save on overhead costs, while still offering high-quality, customized products to their customers.

No order minimums: DTF Printing allows businesses to accommodate orders of any size, with no minimum order requirements. This flexibility enables businesses to cater to a wide range of clients, from small boutique orders to large-scale production runs, ensuring that all customers' needs are met efficiently and effectively.

Disadvantages of DTF Printing

While Direct-to-Film (DTF) Printing offers numerous benefits, it is important to consider the potential drawbacks as well. Some of the disadvantages of DTF Printing include:

Initial investment in equipment and supplies: DTF Printing requires specialized printers, inks, and films, which can be a significant upfront cost for businesses. Investing in high-quality equipment and supplies is crucial for achieving the best results, but it might pose a financial challenge for some companies, especially those just starting out in the industry.

Learning curve for mastering the technique: As with any new technology, there is a learning curve involved in mastering DTF Printing. Businesses must invest time and resources in training their staff to use the equipment and execute the process effectively. This can be a hurdle for some companies, particularly those with limited resources or experience in the field.

Maintenance and upkeep of equipment: DTF printers and other equipment require regular maintenance and upkeep to ensure optimal performance and longevity. This can be time-consuming and may involve additional costs for replacement parts and servicing. Companies must be prepared to allocate resources to maintaining their DTF Printing equipment to ensure consistent, high-quality results.

DTF Printing vs. Other Printing Methods

When comparing Direct-to-Film (DTF) Printing to other popular printing methods, it's essential to consider the unique advantages and disadvantages of each technique. This section highlights how DTF Printing stacks up against sublimation printing, Direct-to-Garment (DTG) printing, and screen printing.

Comparison to Sublimation Printing

Sublimation printing is a process in which designs are printed on a special paper and then transferred to the fabric using heat. This method is typically used for polyester or polyester blend fabrics and is known for producing vibrant, full-color prints that are resistant to fading. However, unlike DTF Printing, sublimation printing is limited to specific fabric types and cannot be used on natural fibers like cotton. Additionally, DTF Printing offers a wider color gamut and can produce more intricate designs compared to sublimation printing.

Comparison to Direct-to-Garment (DTG) Printing

Direct-to-Garment (DTG) printing involves using specialized inkjet printers to directly print designs onto fabric. This method can produce high-quality prints on various fabric types, including cotton, and offers a wide color range. However, DTG printing can be slower and less efficient than DTF Printing, especially for large-scale production runs. DTF Printing also has an edge in terms of durability, as the adhesive powder used in the process creates a strong bond between the design and the fabric, resulting in longer-lasting prints.

Comparison to Screen Printing

Screen printing is a traditional printing method that involves using a stencil and ink to create designs on fabric. This technique is known for its durability and ability to produce vibrant colors. However, screen printing can be time-consuming and labor-intensive, especially when creating multi-color designs. In contrast, DTF Printing allows for more efficient and accurate production of complex designs, as well as the ability to print on various materials. Additionally, DTF Printing is a more eco-friendly option, as it generates less waste and uses fewer resources than screen printing.

Tips for Starting and Succeeding in a DTF Printing Business

Launching a Direct-to-Film (DTF) Printing business can be a rewarding endeavor, but it requires careful planning and execution. Here are some insightful tips to help you establish and thrive in a DTF Printing business:

Choosing the right equipment and supplies: To ensure the highest quality prints, it's vital to invest in the best equipment and supplies, including specialized DTF printers, inks, and films. Research the available options and select products that are compatible with your business needs and budget. Remember, quality equipment will ultimately contribute to your business's success by producing top-notch results.

Investing in quality control tools: Consistently delivering high-quality products is crucial for maintaining customer satisfaction and building a positive reputation. Invest in quality control tools and processes to monitor and maintain the standards of your DTF prints. This will help you identify and address any issues promptly, ensuring a consistently high level of quality across all your products.

Creating unique and eye-catching designs: To stand out in the competitive DTF Printing market, focus on creating unique, captivating designs that cater to your target audience's preferences. Collaborate with talented designers or develop your own design skills to produce original, visually appealing prints that resonate with your customers.

Marketing your products and services: A well-executed marketing strategy is essential for increasing visibility and attracting customers to your DTF Printing business. Utilize various marketing channels, such as social media, content marketing, and email campaigns, to showcase your products and services. Share engaging content that highlights the benefits of DTF Printing and demonstrates your expertise in the field.

Prioritizing customer satisfaction: Customer satisfaction should be at the heart of your DTF Printing business. By delivering high-quality products, offering excellent customer service, and addressing any concerns promptly, you can build a loyal customer base and enjoy repeat business. Remember, satisfied customers are more likely to refer others to your business, contributing to its growth and success.

Embrace the DTF Printing Revolution

In this article, we delved into the world of Direct-to-Film (DTF) Printing, exploring its key benefits, such as high-quality prints, versatility, and eco-friendliness. We also discussed the DTF Printing process and how it compares to other popular printing methods like sublimation, DTG, and screen printing. If you're looking to elevate your printing game and meet the growing demand for sustainable, vibrant, and durable prints, DTF Printing is the way to go. Discover the amazing products and services offered by DTF Transfer Zone, including custom DTF transfers, DTF ink, and supplies, by visiting their website .